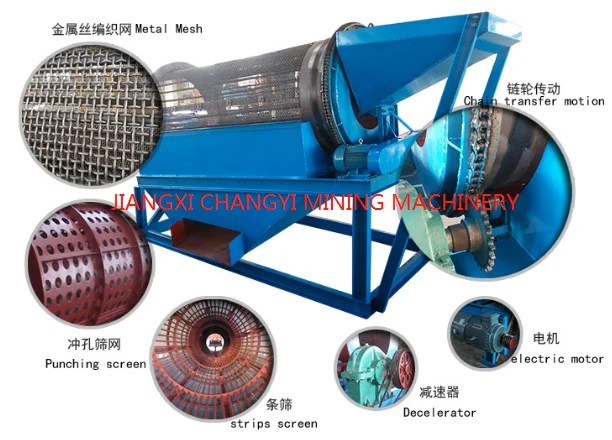

Working Principle of Gold Trommel Washing Plants

From the storage hopper, raw material feeds into the rotary sieve drum, and is lifted up by the

rotation, in the meantime washed by the flushing water as it falls back down. This action is repeated with each revolution along the wall of the drum. The finer material passes through the screen while the larger material tumbles towards its eventual exit at the rear of the drum. The fine size mineral materials are then passed to the downstream process equipment, which can be in various forms, such as centrifugal concentrator, spiral chutes, jig machines etc.

Features of Gold Trommel Washing Plants

The rotary sieve provide a simple, efficient and economical solution to upgrade a wide rang of

material and optimize the subsequent process steps of recovery. This method of screening helps to reduce operating and investment cost and to increase product quality, while allowing rapid and large volume processing.

| Payment Terms of Shaker Table |

| • We usually accept T/T, L/C |

| • T/T: 30% of total amount as deposit, 70% balance before delivery. |

| • We will take pictures of finished products to you before delivery. |

| Way of Packing of Shaker Table |

| • FCL & LCL export standard container 20/40 feet. |

| • FCL: Sea-worthy package. Machines are fixed in container; spare parts are packed in wooden boxes. |

| • LCL: Machines are packed in steel frame with plywood boxes. Customized package is available. |

We provide 12months quality warranty to make sure gravity machine well runs consistently.

Pre-sale services:

a. Professional engineer design the production line for you

b.Recommend suitable equipment according to your special demand.

During-sale services:

a.Pre-check and accept products before delivery

b.Send technicians to the jobsite for guiding the installation and adjustment

c.Training operators and finishing the check to satisfy your requiremnet

After-sale services:

a.Common problem can be solved through web in 24 hours,complex problem can be reacted immediately in 24 hours and solved as soon as possible

b.To establish long-term friendship, we will regulary contact with our customers.

Shicheng Changyi mining machine equipment manufacturing established in 1958,located in Ganjiang River source and Wuyi mountain,is a professional supplier in producing and sale kinds of bearing bushes and mining equipments

We produce high precise vibrating feederJaw crusher,Hammer crusher,Vibrating screen,spiral classifier,ball mill,belt conveyor,shaking table,centrifugal concentrator,spiral chute,jig machine,flotation cell,magnetic separator,rotary scrubber,gold trommel screen,lab mining equipment etc.

Our Company won the reputation of "Jiangxi High Quality Products".

1.what is the raw material do you want to process?

2.what is the capacity per hour do you need?

3.what is the raw material input size?

4.what is the output size of your product?

Please kindly advise above.

Please feel free to contact me online or by email/phone!

Xiaoan Liao

Other Products

-

High Frequency Vibration Screen Machine For Coal Mining

-

High Frequency Vibration Screen Machine In Metallurgy Industry

-

GYX Series High Frequency Vibrating Fine Screen

-

Low Cost Vibration Screen For Gold Mining (1845)

-

Low Price Sand Vibrating Screen (1845)

-

High Effective Vibration Screening Machine (1845)

-

High Quality Vibrating Screen Separator (1445)

-

Vibration Screening Machine For Refractory Materials (1445)

-

Linear Vibration Screen In Chemical Industries (1024)

-

Linear Vibrating Screen For Refractory Materials (1024)

-

Hot Selling Dewatering Screening Machine (1024)

-

Gold Trommel Screen For Sale (1225)

-

Trommel Screening Plant For Gold Mining (1040)

-

Trommel Screen For Coal Mining (1030)

-

Sand Trommel Screen In Stone Mining (1024)